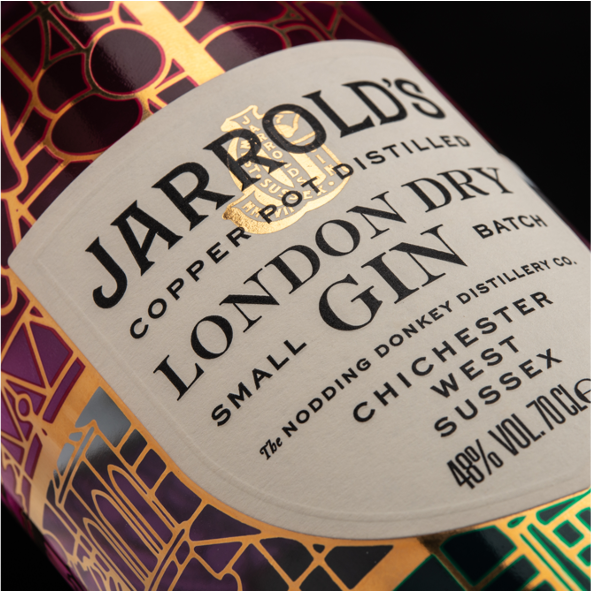

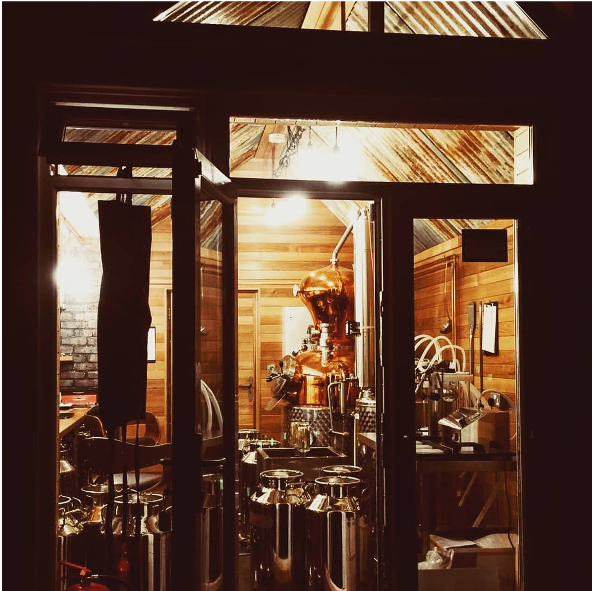

What did you do before creating Nodding Donkey Distillery and Jarrold's Gin? I have worked in the energy sector since I was 18 years old and still do! Whilst I didn’t have any previous experience in distilling, my work has given me confidence in machinery systems, running various equipment plants, and also management systems and processes. Coming in with zero experience has actually been really useful. When I didn’t know something, I just researched it and found people to talk to who have been really happy to impart their experience and knowledge and that has been really refreshing. As a result, it made me really keen to help others in the same position and I’ve helped people in Marlow, Canada, South Africa and Portugal setting up their distilleries. What made you decide to create your distillery and gin? We’ve always been interested in alcohol! We have made various flavoured spirits over the years; vodkas, sloe gins, our own version of Bailey’s, and beer of course, but we were always a little disappointed in the gins we used to buy. When the laws changed to allow gin distillation in smaller volumes, thanks to Alan Powell and budding distillers such as Sipsmith, we settled on the idea of making our own gin as it required a much smaller footprint than brewing beer and we were able to do it from home. Deciding to do it and convincing your wife it would be possible are two very different things, so we went along to the Bombay Sapphire distillery in Laverstoke for a nosey. Nichola quietly walked around taking it all in. Afterwards she turned to me and said…”That’s not rocket science, I think we could do that.”, and so it began. What’s the inspiration behind your gin? The inspiration is really about the full flavour and alcohol strength which we wanted to shine through almost any mixer. While I was working in Iraq, I had come across Noomi Basra or Persian limes, thanks to a friend and colleague. They are used in so many elements of Middle Eastern cooking and there was always this fantastic citrus note in so many dishes, even teas and coffee! I thought it would provide the distinctive and inspirational quality missing in a lot of gin available at the time. Can you tell us more about your distillery? The distillery room is on the side of our house. It’s a small room but from there we are able to do the distillation, cut back the gin and bottle it. Labelling is done at the kitchen table. We did a lot of the work ourselves and the whole family got involved. We wanted somewhere nice to spend our days and also to show visitors. The outside brickwork of the house is exposed on one side and the rest of the walls are clad in cedar. That, along with a sealed but rusted tin roof, all look great with all the copper and stainless steel of the still. It really isn’t what a lot of people expect to see when they walk in. Can you tell us more about your still? The still is a 240 litre single shot copper pot still, electrically powered with a water bath that indirectly heats up the contents for distillation. It’s probably the smallest commercially viable size you can buy and just right for a full day’s distilling. It’s very quiet and almost odour free. Any bigger than that and I would have to distill into the night. The still is a really beautiful bit of engineering from Kothe in Esslingen, just outside Stuttgart in Germany. I went over to the factory before we had even built the distillery, and it turned out to be such a useful and fun experience. I had the opportunity to view the factory and see the quality of work going on at various stages of the build which gave me the confidence to spend quite a large sum of money on equipment that I essentially knew nothing about. The really fun part was going to the factory owners’ father in law’s house (who had passed the business down to him). It was astonishing. Pulling up in front of the house, it seemed everything was copper, even the double garage doors. There was a complete distillery from grain to glass in the grounds and an underground bunker which held two long tables seating 54 people for tasting events, a bar, and locked iron bar gates at one end which were holding his whisky barrels. What is your distillation process and can you tell us more about the botanicals? We developed the recipe ourselves and distill it ourselves which we are very proud of. Because our only dry gin is a London Dry Gin, we have to make it to a specific set of rules. Sugar content has to be very low, which is why we use a premium grain neutral spirit at 96.6% ABV. Everything we use is natural, distilled above 71% and nothing is added to the distillate afterwards other than water. We use only seven botanicals, which we list on the back of the bottle, but we use almost twice as much juniper as most other distillers do, which of course really helps with the flavour. It also gives our gin a lovely smoothness on the palate when drunk neat over ice. The juniper, along with four other botanicals are added to a watered down spirit of 60% ABV and left to macerate for a few hours. After that is where we do the first thing a bit differently to lots of other distillers. Instead of going straight into the distillation, we add more water and cut it back to 30% ABV. Then we add the last two botanicals to the basket above the spirit and start the still. We were told by the Kothe team that cutting the spirit back to 30% would give us a much smoother and flavourful spirit and we agree with them. It means we can only make half as much each run, but we’d rather work harder for a nicer product, so we will never deviate from this process. Here’s the next bit we do a little differently. We distill it slowly, minimising the water content and allowing the steam to capture all those lovely oils from the basket and hold the juniper and coriander seed oils up and over the vapour pipe. After it’s been distilled, we let it rest for at least a couple of weeks before cutting it back to our 48% ABV bottling strength. The water is charcoal filtered first and then passed through a reverse osmosis machine so it is incredibly pure. What can gin lovers experience if they visit the distillery?

We don’t offer tours as such but if people are interested in seeing the distillery we are happy to show them around. We love seeing people’s faces as they walk through the kitchen, into the garden and then turn around into the distillery. It’s really not what you expect to find in someone’s garden in the middle of the town. We tend to offer a distillery experience as charity auction gifts for local charities and have done several of these with great success. What have been the biggest challenges and achievements so far? When you’re doing something so new there are so many challenges that you almost forget the last one as you seem to move onto another so quickly. There have been so many firsts for us in this process and it’s been a massively steep learning curve but we are incredibly proud to have been awarded a Silver Outstanding award by the IWSC just four months after we opened for our London Dry Gin. As with many other businesses, we have been challenged and continue to be so with all of the disruption due to COVID-19 and chaos in the government and the world generally which has pushed up our costs hugely. We’re proud to have come so far and will continue to produce our gin in the same way as we have done from the beginning. We would like to say a big thank you to all our customers who have supported us throughout. You Might Also Like...

Comments are closed.

|

RSS Feed

RSS Feed