|

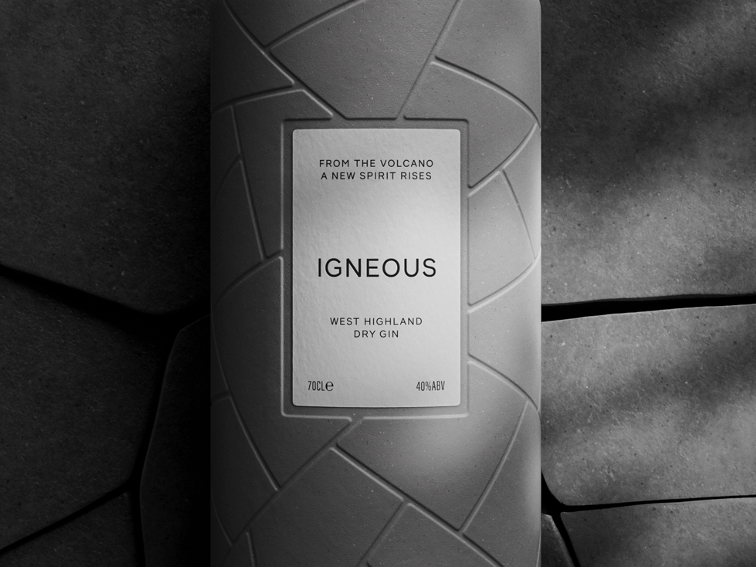

What did you do before establishing Igneous Distillery? Before creating Igneous Gin I was a self-employed Painter & Decorator for nearly 12 years and Katie was a Manager in Retail at M&S for about 14 years. We both came to point where life had changed so much and we always said we wanted to do something together. What made you decide to produce gin and what's the inspiration behind your gin? It was really fuelled by the change in our life from losing my parents in quick succession and wanting to create something from our loss. We have both always loved gin, although neither of us are big drinkers, but we love the artistic nature of crafting something that is so heavily linked and moulded by a place of significance. We love Ardnamurchan, both our sets of parents lived here at one time or another, we were married on the peninsula and my parents now rest here. We wanted to carry on their quirky, hard-working ethic but thought it was best to do it with something we were passionate about. What is the meaning and story behind your brand name? The word Igneous is the name of Volcanic rock that surrounds us and that we dug our private water supply through. We truly believe that the water we use has such a special cocktail of minerals, which we don’t strip from it, and in turn they help to make our gin so smooth. Can you tell us more about your distillery and your still? The Distillery itself was adapted from my parents workspace for their antiques business. We stripped it back to a bare canvas before upgrading electrics, utilities and layout to make it fit for purpose as a Distillery, including designing it to be ATEX (Anti-Explosive) safe. We then installed our Genio 250 Litre still. We opted for this setup mainly due to power restrictions. The whole distillery is on a single phase supply due to the remote location of the building. There were very few options other than using open flame burners or steam, which obviously have their own challenges. > The distillery transformation while in progress: Can you tell us more about your distillation process? We use a simple pot distillation process when making Igneous West Highland Dry Gin. We have the option to use the botanical baskets that allow us to see the botanicals throughout the process, however we tend to use the method of bagging the botanicals at the base of the rectification column. We use a couple of interesting botanicals but we try not to tell too many people about these, however, we find the one botanical people are most intrigued about is the Bog Myrtle which grows in abundance around the volcano crater and peninsula. Can you tell us more about your bottles and how you make them? The bottles are ceramic stoneware bottles, they really are Katie's babies. She uses a process called slip casting. Basically we take our raw clay, make it into a ‘slip’ by adding water, stain and a few other materials. This is then poured into our custom design and made moulds. After a period of time, we pour the slip back out to be used again. What is left in the mould is the bottle in a very wet, pliable form. We remove them from the moulds to dry, before they are hand finished. Once dry and prepped, they go into our kiln and are fired to 1240ºC. This is ‘Stoneware,’ and the clay vitrifies which is a chemical process meaning it melts the molecules together to form a glassy like barrier and they become water tight. It’s a long and labour intensive process, but we feel this really stands us apart and adds to the true craft nature of what we are doing. > Katie crafting each Igneous Gin bottle individually: What was the journey like from concept to launch? Long! It took us the best part of 4 years to get our gin launched. As with everything that’s worth doing, it’s worth doing right and we probably took longer than we needed too. We were also managing this from a distance as our home life is down in Yorkshire and the logistics of creating a business over 300 miles away is tricky. We were both working full time throughout the process, as well as raising our two boys so we definitely had our hands full, but we took the many bumps in the road as they came and dealt with them one at a time. I look back now and I wouldn’t have done it any differently. We did this completely ourselves, self-funded and with minimal help apart from specialist areas such as our branding team at Jam Hot and Kate and David who helped us with our ceramic mould production. These guys were invaluable to us. We kept on getting asked along the way, do you regret it? Honestly, we had days where we wobbled, but then I would always say, how do you regret something you are so passionate about achieving. What is your ambition for your distillery and brand in the years to come? We strive to make Igneous Distillery a staple brand within the craft gin industry. One that is renowned for coming from humble beginnings but grows through genuine hard work and graft. We want to show the industry that the thing that can make a Gin so special is not the ability to churn out tens of thousands of bottles a year, each one identical to the last, but actually create products that although the same, have their individual quirks. Craft gin after all is meant to be a craft. What are your favourite ways to drink your gin?

We both like it a little differently, I really enjoy a Gin neat with ice. But my favourite has to be a Negroni. Katie is a G&T lover through and through as long as it’s a premium Mediterranean tonic Desert Island Gins: Which 3 gins would you take with you and why? “Great question! We are in agreement here; it would have to be Stranger & Sons Indian Spirited Gin, Sabatini Gin and Theodore Pictish Gin. We loved all three of them and they are all very different gins in their own right. But that’s why we would want them, a nice variety of fabulous flavours and aromas.” What's next for you and Igneous Gin - any exciting plans? Onwards and Upwards! We are obviously very, very new and have a lot of hurdles to overcome still. We need to look at our internal operational structure and realistically we cant keep doing it on our own. Having two boys under 9 is hard work by itself let alone running a gin distillery as well. But also we have grand plans to add our refill pouches as we know most of our customers will never want to get rid of their bottles (and this is exactly what we wanted!). Repurposing or reusing is our aim, recycling is such a flippantly used term these days and doesn’t always truly represent the best option for the environment. We also are working on something rather cute if we do say so ourselves, so watch this space! You Might Also Like...

Comments are closed.

|

RSS Feed

RSS Feed